Looking to test out the new features of tvOS 17.5 Developer Beta 2? Check out this short guide on how to download and install on your Apple TV.

5 Questions You Should Never Ask Siri: Avoid These at All Costs

While Siri can be an essential part of an iPhone or Apple Watch experience, here is a list of things that you should never ask this personal assistant.

iPhone 17 Plus Screen Size Might Be Smaller Than Current Plus Variant, Says Report

Well, would you settle for an iPhone that’s lacking that Plus factor?

iPhone Enjoys About Double the Popularity of the Mac Among Apple Users, reveals Study

A report reveals how deeply Apple customers are invested in ecosystem, claiming over 90% customers have an iPhone nearly double the Mac’s.

You Can Now Download the Delta Emulator From the App Store

You can now play a wide range of retro games on your iOS device with Riley Testut’s Delta emulator, available directly from the App Store.

Apple Plans To Manufacture Camera Modules in India but Not Their Phones With 3 Cameras

As Apple looks to diversify iPhone production away from China, they’re seeking camera module suppliers in India. Talks with Murugappa Group and Tata’s Titan Company could create a more localized supply chain.

WhatsApp Introduces Chat Filters To Help Declutter Your Messages

Chat filters for WhatsApp are here to effortlessly sort chats, find messages fast and ditch the endless scroll.

WhatsApp Is Working on a Feature To Pin Channels for iPhone

WhatsApp is working on a new pin channels feature for iOS to let users pin their preferred channels at the top of the list.

Report: China Might Be the Culprit Behind Recent Apple Spyware Attacks

A report suggests LightSpy, a piece of spyware with Chinese connections, was responsible for the most recent attack on Apple iPhones.

iOS 18 Set To Bring Major Boosts to Apple Notes

iOS 18 is expected to bring a ton of new features to Apple Notes, such as integrated audio recording and support for mathematical notations.

Apple Stops Suggesting Palestine Flag for 'Jerusalem' Searches, Ending Controversy

iOS 17.5 beta 2 doesn’t suggest Palestine flag now when you type Jerusalem after updating your device, putting an end to controversy.

Editorial mistakes & covering rumors at The Mac Observer

We acknowledge and apologize for this mistake. This source’s opinions were made public in one of our articles (now retracted) without thorough verification from our editors. All parties involved in this process are no longer part of our team.

How To Install visionOS 1.2 Developer Beta 2

Looking for ways to install the new visionOS 1.2 Developer Beta 2? This guide has everything you need to know.

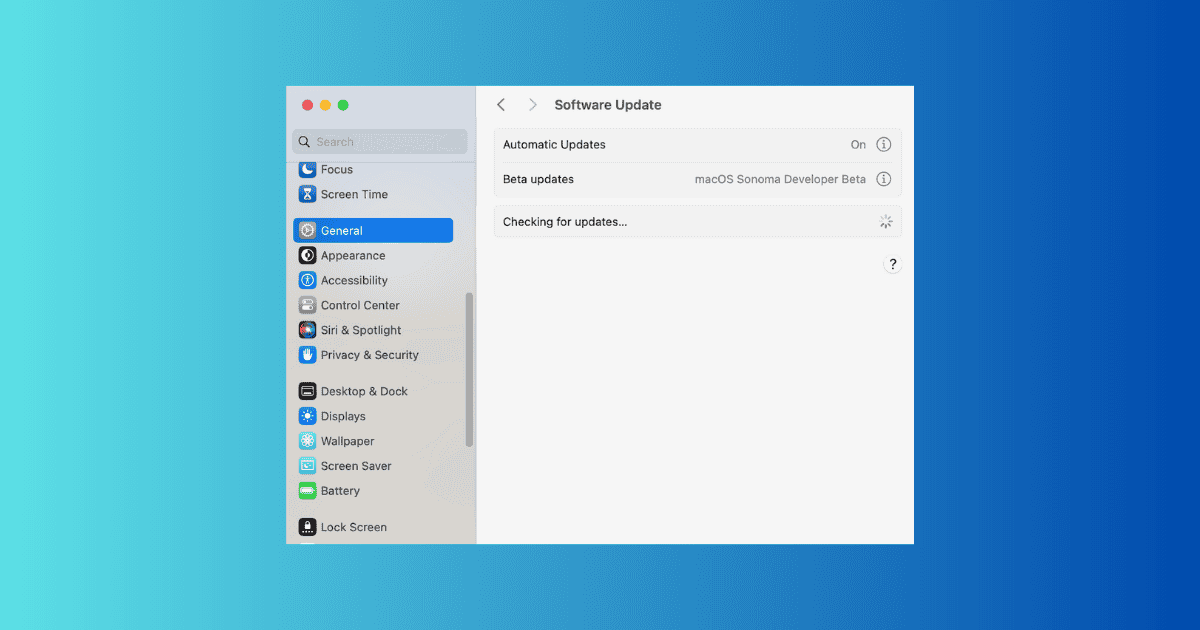

How To Install macOS Sonoma 14.5 Developer Beta 2

The new macOS Sonoma 14.5 Developer Beta is here. Check out this quick guide to find out more and install the version.

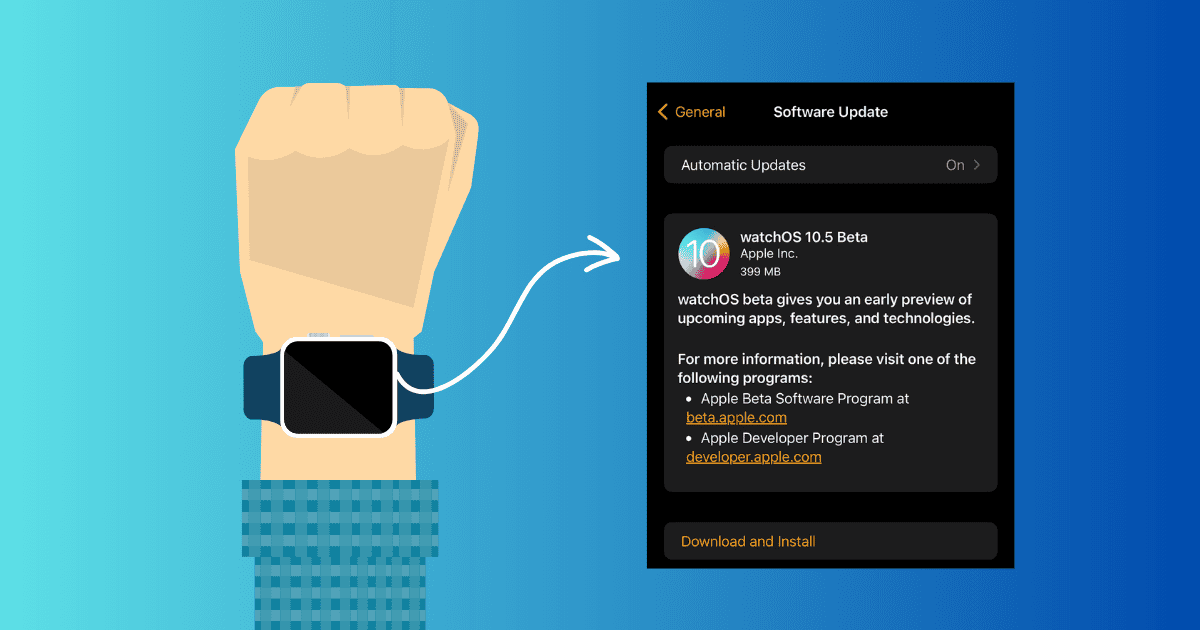

How To Install watchOS 10.5 Developer Beta 2

Looking to install the watchOS 10.5 Developer Beta 2? Check out all the steps and a quick guide to know more.

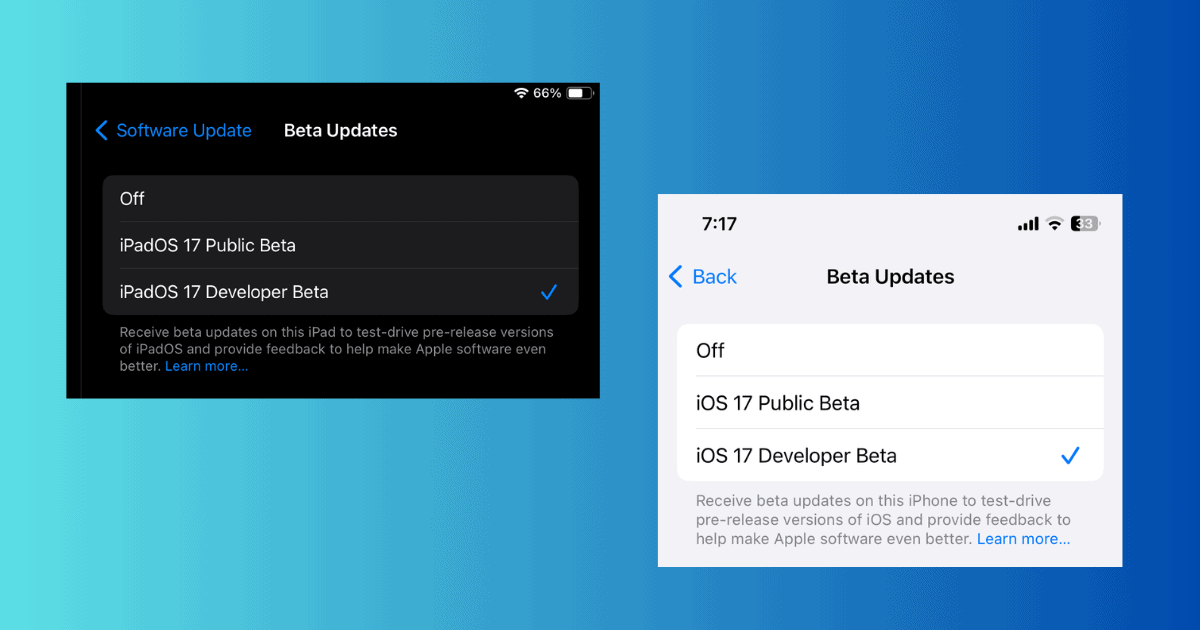

How To Install iOS 17.5 & iPadOS 17.5 Developer Beta 2

Are you trying to install the iOS 17.5 & iPadOS 17.5 Developer Beta 2 on your devices? You’re in the right place!

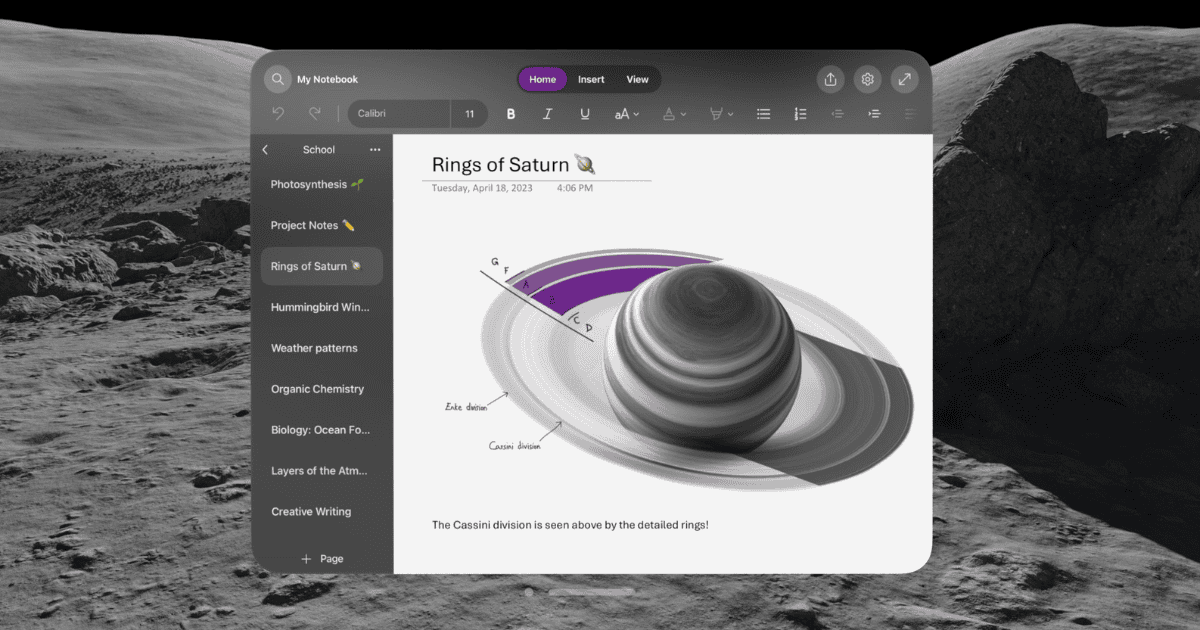

Microsoft's Note-Taking App 'OneNote' Now Available on Apple Vision Pro

Microsoft OneNote lands on Apple Vision Pro! Take notes, build digital notebooks, and manage tasks directly in mixed reality. This new app offers familiar OneNote features like organization tools, cloud storage, and collaboration. Learn more about functionality, installation, and supported accounts for Apple’s latest MR headset.

iOS 17.5 Beta 2 Introduces App Downloads From Websites for EU Users

Apple’s iOS 17.5 Beta 2 update introduces the ability for users in the EU to sideload apps directly from a developer’s website.

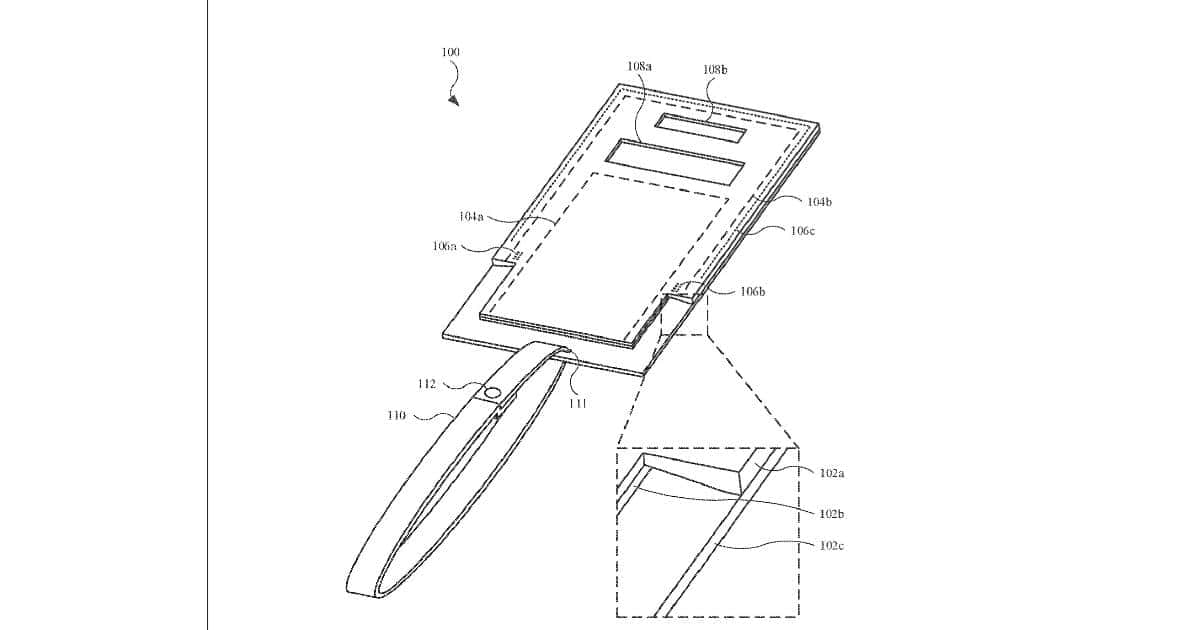

Apple Patent Hints at Future Wearables With Health Monitoring Capabilities, Apple Watch Who?

An Apple patent filing reveals technology for future wearables that could monitor biometric data and location to deliver real-time health advice and potentially lifesaving aid. This describes a system that tracks health data and overlays suggestions within a mixed-reality system, potentially designed for continuous wear.

Apple Highlights Trade-Ins and Recycling Your Devices for Free in Pre-Earth Day Initiative

Apple has placed a banner on its website ahead of Earth Day on April 22nd, reminding users that can recycle old Apple devices for free.

Future Apple Watch Might Throw a Lifeline with Drowning Alerts, Hints Patent

Apple may be planning to add a feature to future Apple Watches that could help prevent drowning, according to a recent patent.

Apple Experimenting With a Magsafe Wallet and iPhone Case Hybrid

Apple is potentially expanding the MagSafe lineup with a new patent hinting at a case integrating a wallet and lanyard.

Lossless Music Coming to Spotify With New “Music Pro” Subscription

Recent rumors suggest Spotify will finally launch a lossless music tier after years of delays and wait from fans and users.

Tech Giants Like Apple Can Now Face Fines Upto 20% for Anti-Competitive Tech Practices in Japan

Japan proposes significant increases in antitrust fines for tech companies engaging in anti-competitive practices, potentially reaching 20% of sales. The revisions target restrictions on app market access, mirroring a global trend towards regulating Big Tech.