President Trump tours Texas at an Apple facility in Texas along with Apple CEO Tim Cook as soon as next week, although no official announcement has been made.

manufacturing

Foxconn Centers in Wisconsin Aren't Being Developed

Foxconn promised it would build five centers in Wisconsin that would each bring 100-200 jobs. But now it says they aren’t being developed.

Mac Pro Made in USA, Oprah's Book Club Returns – TMO Daily Observations 2019-09-23

Charlotte Henry and Andrew Orr join host Kelly Guimont to discuss the Mac Pro’s US-based manufacturing, and Oprah’s book club selection (don’t call it a comeback).

Confirmed: Apple Moves Mac Pro Manufacturing Back to Texas

Despite news in the past saying Apple was moving Mac Pro manufacturing to China, today a report says it will stay in Texas.

Apple Starts Using Recycled Rare Earth in Taptic Engine

Apple said today it will use recycled rare earth materials in the Taptic Engine of the new iPhone 11 models.

Apple Involved in TSMC Patent Lawsuit

GlobalFoundries accused TSMC of patent infringement involving 16 patents. Apple is cited in three of them.

Salmon Gold, Gift Card Shenanigans – TMO Daily Observations 2019-08-13

Andrew Orr and Charlotte Henry join host Kelly Guimont to talk about RESOLVE and Salmon Gold, and when gift cards go wrong.

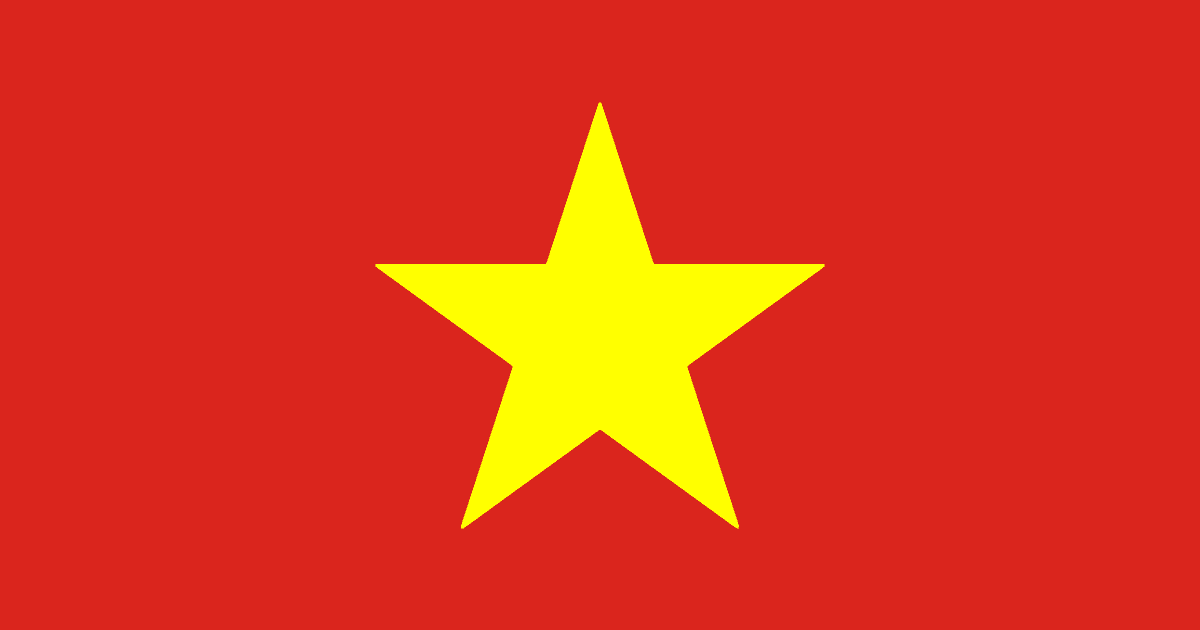

Vietnam Might Be the Next iPhone Manufacturing Center

Due to the trade war between the United States and China, companies are looking to put their eggs into more baskets. Vietnam could be one of them.

Apple has homed in on Vietnam and India as it intensifies its search for ways to diversify its supply chain. Nintendo has accelerated a shift in the production of its Switch console to Vietnam from China, according to Panjiva, a supply chain research firm. The Taiwanese electronics behemoth Foxconn, a major assembler of iPhones, said in January that it had acquired land-use rights in Vietnam and had pumped $200 million into an Indian subsidiary. Other Taiwanese and Chinese partners to Apple have indicated that they are considering ramping up operations in Vietnam as well.

2020 iPhones Could Get 5-Nanometer TSMC Chips

Rumor has it that Apple’s supplier TSMC could move to a 5-nanometer process for its chip manufacturing on 2020 iPhones.

Japan Power Outage Ruined 6 Exabytes of Hard Drives

The cost of flash storage could increase in the future due to a power outage in Japan. Western Digital and Toshiba were affected.

2019 Mac Pro Production is Moving to China

Apple’s 2019 Mac Pro production will be moved to China. Quanta Computer Inc will be the contractor.

iPhone and the US-China Trade War

Jason Dedrick, Greg Linden, and Kenneth L. Kraemer broke down the cost of the iPhone and showed how China doesn’t get as much value from iPhone exports as we think.

So what about all of those famous factories in China with millions of workers making iPhones? The companies that own those factories, including Foxconn, are all based in Taiwan. Of the factory-cost estimate of $237.45 from IHS Markit at the time the iPhone 7 was released in late 2016, we calculate that all that’s earned in China is about $8.46, or 3.6% of the total. That includes a battery supplied by a Chinese company and the labor used for assembly.

Pegatron Looks to Expand Product Assembly to More Countries

Apple manufacturer Pegatron will start assembling MacBooks and iPads in Indonesia starting in June.

The 2019 Apple Supplier Responsibility Report

The 2019 Apple Supplier Responsibility Report has been released. The report is broken down into three categories.

Examining Apple's Recycling Ambitions

Maddie Stone wrote a great dive into Apple’s recycling ambitions and the company’s quest to some day stop mining resources.

For a company that sells over 200 million smartphones a year, along with millions more tablets and computers, achieving what sustainability wonks call a “circular economy” will amount to a complete overhaul of everything from how Apple devices are manufactured to what we do with those devices at the end of their lives…The question is whether that’s a future Apple truly wants—or one that its investors will allow.

Social Media Responsibility, Manufacturing on Apple's Scale – TMO Daily Observations 2019-01-28

Bryan Chaffin and Charlotte Henry join host Kelly Guimont to discuss responsibility in social media and manufacturing on Apple’s scale.

In 2018 Apple Spent $60 Billion With 9,000 U.S. Suppliers

U.S. suppliers may have trouble making custom screws for Apple products, but other components can be manufactured without issue.

Here's Why iPhone Assembly Doesn't Happen Here

Apple relies on China for a huge part of its manufacturing needs. But why can’t the company bring it back to the United States? Custom screws.

The challenges in Texas illustrate problems that Apple would face if it tried to move a significant amount of manufacturing out of China. Apple has found that no country — and certainly not the United States — can match China’s combination of scale, skills, infrastructure and cost.

Manufacturing and cheap labor are the reasons why Apple and other companies go to China. The GOP can talk about bringing jobs like that back, but it’s not an easy problem to solve.

Tim Cook Is a Failure at Operations

Operations are supposed to be what Tim Cook does best. Under Steve Jobs he was the Chief Operating Officer at Apple. And while he may have done a great job there, he is a failure at it as CEO.

Apple Manufacturing, AI Regulation – TMO Daily Observations 2018-12-18

Bryan Chaffin and John Martellaro join host Kelly Guimont to discuss Apple’s attempts at manufacturing in the US, and how to regulate AI.

How Did Tim Cook Fix the Apple Supply Chain?

The entire Quora article is worth reading, and it compiles information from other articles to paint a picture of Tim Cook’s genius.

Apple Faces Lawsuit From Sapphire Glass Manufacturer

Details about the lawsuit aren’t known, however the damages that Hebai Hengbo wants is worth more than US$75,000.

Trump Claims 3 Apple Manufacturing Plants Will Come to U.S.

President Trump claims in an interview that three Apple manufacturing plants will be built in the United States. Apple declined to comment, although Foxconn is reportedly considering Wisconsin as a plant location.

Apple Chip Supply Speeds Up, While Non-Apple Supply Slows Down

It seems as if smartphone manufacturers are holding off their endeavors until Apple releases the iPhone 8 later this fall.